TSU scientists keep high-strength magnesium alloys

Magnesium alloys with a strengthening LPSO phase (long-period stacking-ordered) were only invented in the early 21st century and are not fully studied yet. Such alloys have outstanding mechanical features, and that is the reason why they have great application potential. Nowadays, we know about the first track record of using such alloys for manufacturing component parts of internal combustion engines (ICE or IC engine), including a block of small-sized ICE cylinders, cylinder-piston group details, ICE pistons, etc.

“The tensile strength and ductility of such alloys turned out to be on the same level or higher than those of high-quality structural steel, despite the fact that magnesium is 4.5 times lighter than iron, meaning that LPSO alloys specific strength is at least 4.5 times higher than steel’s specific strength. This fact allows us not only to use magnesium LSPO alloys in products working under normal conditions–for example, in laptops, mobile phones, bicycles, and automobile wheel disks – but also in products used under conditions of extreme loads and aggressive environments,” the leading researcher of the Oxide Layers, Films, and Coatings research department (rus. НИО «Оксидные слои, плёнки и покрытия»), Ph.D. in Technology Anton Polunin explains. “However, the LPSO phase provokes corrosion, which is why LPSO alloys’ surfaces have to be protected.”

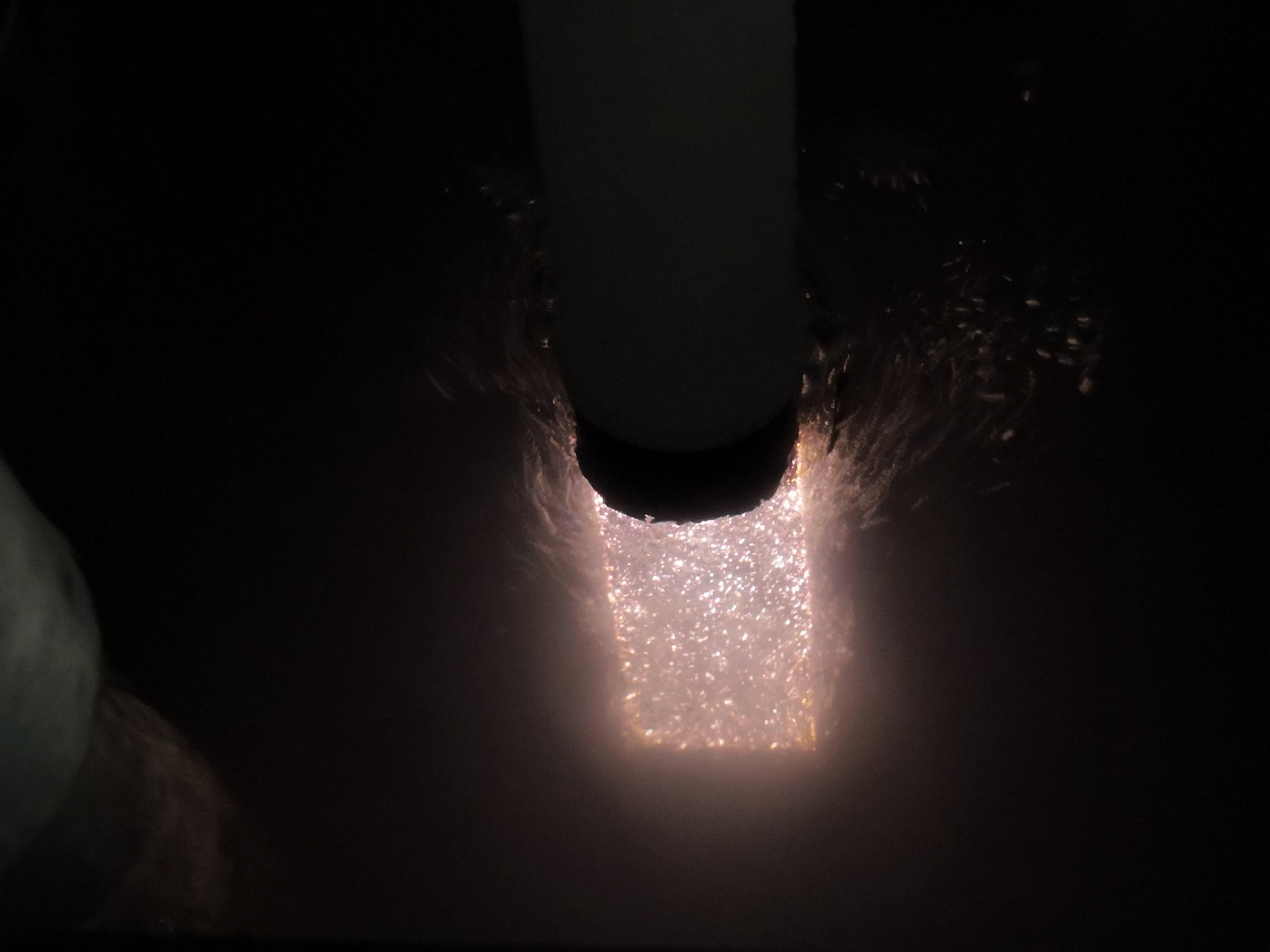

Plasma electrolytic oxidation (PEO) has a good effect on protecting the surface of products made of aluminum, magnesium, titanium, and some other alloys. Ceramic metal-oxide layers or coatings are formed on the surface, which can increase wear and corrosion resistance tenfold. Importantly, it is also an environmentally friendly technology.

Oxide Layers, Films, and Coatings research department employees study and perfect the PEO technology at Togliatti State University under academic supervision of professor, Doctor of Physics and Mathematics Mikhail Krishtal, with the participation of leading researcher from the Israel Institute of Technology (Technion), theoretical physicist, PhD Alexander Katsman, and the support of the Russian Science Foundation.

“It would seem that this is the solution for LPSO alloys, but PEO on LPSO alloys does not give the expected result under normal conditions. The oxide layer is very loose and fragile, and the LPSO phase is also to blame for this. While dramatically increasing the volumetric mechanical characteristics, it also has a negative effect on the surface, reducing not only the corrosion resistance but also the possibility of obtaining a high-quality ceramic layer by PEO,” says Mikhail Krishtal.

A significant increase in current frequency during PEO will have a positive effect, but even that is not enough.

“Technically, the best result is obtained by the combined technology developed by Spanish scientists, in which a sealing compound deposited from the electrolyte is applied to the porous ceramic surface after PEO. But this leads to longer processing times and a significant increase in the cost of the final product,” says Mikhail Krishtal.

New hybrid plasma electrolytic technologies, which include the introduction of nanoparticles of various oxides into the electrolyte during PEO, are being developed at Togliatti State University on the basis of PEO. During the PEO process, these particles are embedded into the oxide layer being formed. Remarkably, even tiny amounts of additives can have a huge effect.

That is exactly what TSU scientists were able to obtain by adding silicon dioxide nanoparticles (basically, sand nanoparticles) into the electrolyte during high-frequency PEO of LPSO alloys.

“As a result, the porosity of the ceramic layer decreased by almost a factor of 3, the average thickness and adhesion of the layer increased by about a third, and the corrosion current density decreased by about a factor of 5.5. These values correspond to the best result for LPSO alloys with two-stage combined PEO-based technology. At the same time, our technology is not more expensive than conventional PEO and even allows us to reduce the processing time, obtaining the required result,” summarises Mikhail Krishtal.

Thus, TSU has found an opportunity to eliminate the surface disadvantage of LPSO alloys and fully develop the potential of their unique volumetric mechanical properties in products that can be applied in the aviation and rocket-space industries in particular. At the same time, the speed of processing such products and its cost is reduced, which makes the technology economically efficient.

The scientists described the results of their research in the article The effect of silica NPs incorporation on protective properties of oxide layers formed by PEO on Mg97Y2Zn1 alloy with LPSO-phase, which was published by Heliyon, a monthly interdisciplinary peer-reviewed, highly rated (Q1 by SJR, Impact Factor 2023–4.0, indexed by Scopus and Web of Science) scientific journal belonging to one of the world's largest publishers, Elsevier BV.

615

views